DWT Purge Gas Saver

For pipes and tanks

- Works on all non-magnetic metals

- Diameter from 300 mm

- Wall thickness up to 8 mm

- Saves up to 90% gas

- Fast start of welding job

Danh mục: Pipe Purging

One of the time consuming and expensive operations when welding pipes, is the purging. To ensure that no oxidation occurs on the inside of the pipes mostly a purging with gas is made. This fills the pipe with gas and the pipe is continuously flushed during welding.

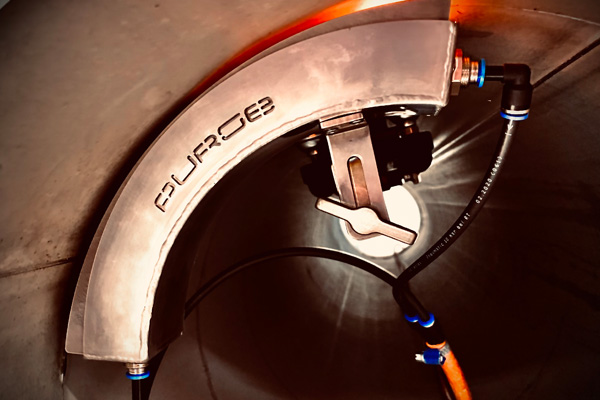

Imagine that you could just apply gas where the welding takes place, and that the gas inside the pipe follows the torch on the outside of the pipe.

- Through the utilization of strong magnets,the Purge Gas Saver always follows the torch

- Due to the 360° wheels the Purge Gas Saver can be slid sideways and through elbows

- No need for attaching wires or similar tools to the Purge Gas Saver. Simply slide it out when you are finished welding

- The gas consumption can be reducedby up to 90% depending on diameter and length of pipe

- Avoid long flush times and uncertainty of the ppm l evel during the weld.

- We offers a complete package ready to use for pipe applications.

Advantages

STRONG MAGNETS

Through the utilization of strong magnets, the Purge Gas Saver always follows the torch

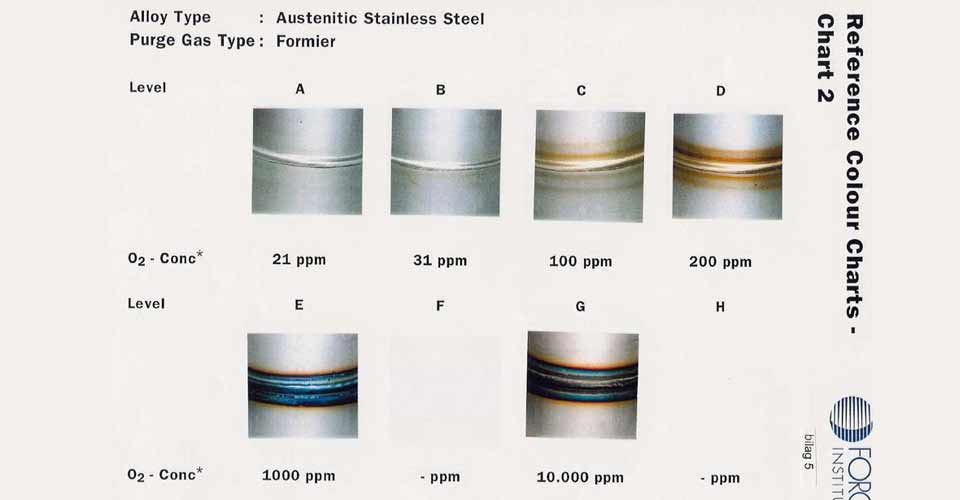

COLOUR CHART PIPE PURGING

The chart shows the respective state of corrosion depending on the oxygen content during welding