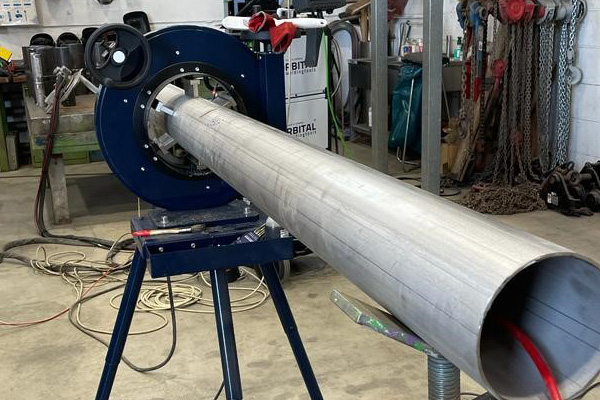

Orbital Pipe Saw

Perfect cut for orbital welding

- Precision Cutting

- Optimal Welding Results

- Variable Speed Control

- Powerful Performance

- For all materials and pipes up to 20,47″

Before pipe segments are joined together by means of orbital welding, the individual parts naturally first need to be cut to size. A professional pipe saw from DWT ensures that the cut surfaces fit together or each other as precisely as possible, ensuring an optimum result in the subsequent welding process. Our orbital pipe saws have a continuously variable electric drive. The speed range is from 20 to 420 rpm, and the torque ranges from 120 to 330 Nm.

In terms of squareness, they offer a cutting accuracy that deviates by less than 0.25 mm from the intended measurement. The rotary crank, which comes as standard, further optimizes the cutting quality and also extends the service life of the saw blades.

- Precision Cutting: Our saws ensure that pipe segments are cut perfectly, providing an optimal fit.

- Optimal Welding Results: A precise cut guarantees the best results in the subsequent orbital welding process.

- Variable Speed Control: The orbital pipe saws come with a continuously adjustable electric drive, with speeds ranging from 20 to 420 rpm.

- Powerful Performance: Torque ranging from 120 to 330 Nm.

- Superior Cutting Accuracy: These saws offer a cutting precision that deviates less than 0.25 mm from the intended measurement.

- Included Rotary Crank: This not only enhances cutting quality but also prolongs the lifespan of the saw blades.

Product Overview

Advantages

HIGHEST CUTTING ACCURACY

Regarding perpendicularity, the cut’s accuracy deviates less than 0.25 millimeters from the target

REDUCED POST-PROCESSING NEEDS

The precision of the cut typically means that there’s less need for deburring or further finishing