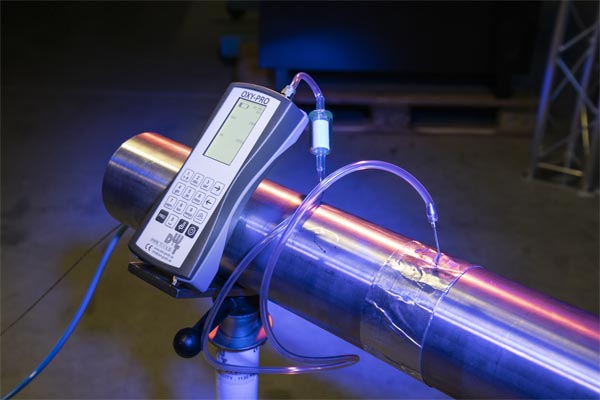

Weld Purge Monitor Oxy Pro

Accuracy up to 5 ppm

- Simple menu navigation

- LED display, parameter entry by membrane keyboard

- Measuring range 5 – 999 ppm O2

- Suitable for inert gases and gases with hydrogen content of max. 10 %

- Measuring cell made of zirconium oxide

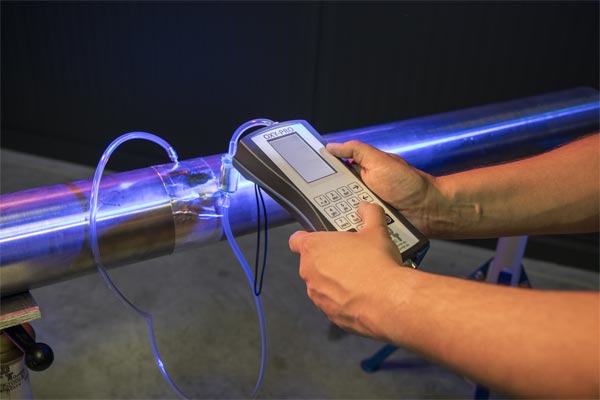

Specially developed for flexible use on construction sites and in the workshop, oxygen analyzer facilitate the welding of stainless steel, since the oxygen concentration can be displayed with an accuracy of up to 0.0005% (5 ppm). Before taking measurements of the welding environment, the oxygen analyzer must be calibrated according to the normal oxygen concentration in the air (20.9%).

The meter maintains calibration even if the device is turned off in the meantime. It is important to ensure that the calibration is repeated at regular intervals. The instrument has built-in temperature compensation to guarantee reliable measurement results at the respective working temperature. Large, unexpected temperature changes can change the measurement results until the temperature of the sensor has stabilized.

- Suitable for inert gases and gases with a hydrogen content of max. 10 %

- Temperature controlled zirconium sensor

- USB interface for storing parameter sets

- Documentation of residual oxygen value, date, time value and name of the project

- Illuminated LED display with simple menu navigation

- Parameter input via keyboard

- Maintenance-free measuring cell made of zirconium oxide

- Long service life through intelligent cell management

- Freely adjustable working range

- Reminder of the validation process

- Robust plastic housing with protective rubber frame

Advantages

BEST ACCURACY

The oxygen concentration can be displayed with an accuracy of up to 0.0005% (5 ppm)

PRICE INCLUDES

Hose set 1m, including filter and stainless steel probe

Test certificate (validation)

Transport case

Power supply unit

ILLUMINATED LED DISPLAY

Simple menu navigation and visual signal during the measurement when the measuring value is not achieved yet